Submit feedback

About Us

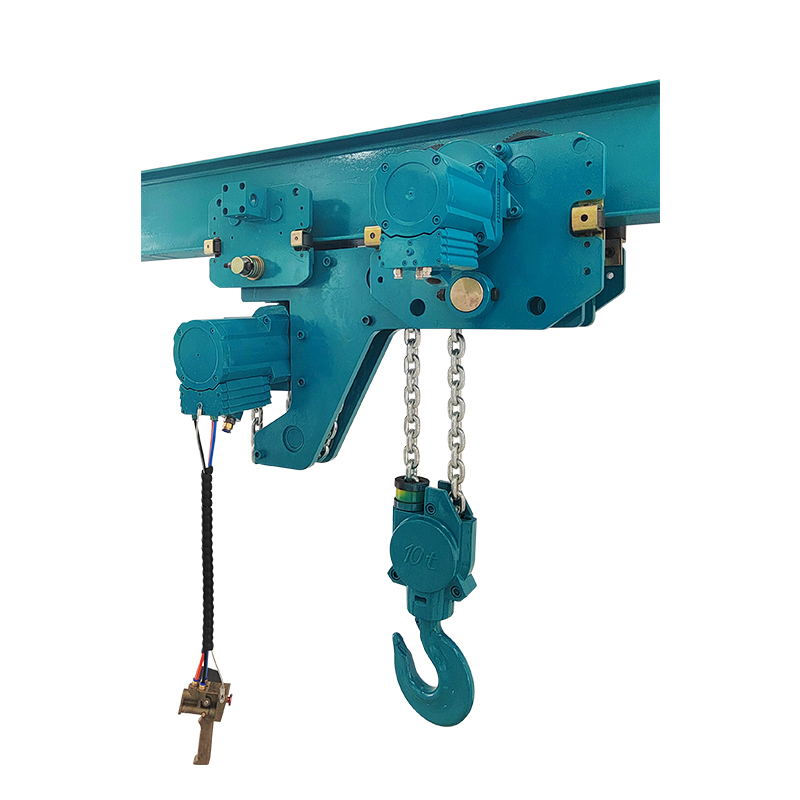

Anhui Gaston Precision Machinery Co., Ltd. is a professional manufacturer of pneumatic motors and equipment that integrates design, research and development, production, sales, and service in China. We are Custom AMP3-R Helical gear reduction motors Manufacturers and AMP3-R Helical gear reduction motors Suppliers. The company was founded in 2009 (Shanghai Togao Precision Machinery Co., Ltd., Kunshan Gaston Precision Machinery Co., Ltd.) and was founded in 2018. Currently, the company has companies in Shanghai, Suzhou, and Guangzhou, covering an area of 20 acres. The factory has more than 60 sets of processing and testing equipment, including a large four axis machining center, CNC inclined guide horizontal lathe, CNC vertical milling machine, ordinary lathe, outer circle grinding, quilting, etc. The machining workshop has CNC shearing machines, CNC bending machines, various types of welding machines, etc., and has strong machining capabilities and high machining accuracy. The sheet metal workshop has CNC shearing machines, CNC bending machines, and other types of welding machines. Processing various related non-standard equipment.

The company has been committed to product innovation for many years, focusing on the updating and upgrading of pneumatic motors. With fine concepts and continuous investment, it has created a creative design team and has designed multiple innovative pneumatic products. Currently, it has independent intellectual property rights and has obtained more than 30 product patents.

The company's main products include pneumatic motors and a series of products such as pneumatic hoists, pneumatic winches, pneumatic mixers, pneumatic emulsifiers, pneumatic explosion-proof pumps, pneumatic mixers, pneumatic fans, and industrial automation equipment pneumatic control system engineering developed based on specific production needs.

The company strictly follows the ISO9001 quality management system for product design, production, assembly, and testing. With the efforts of all employees, the company has passed the ISO9001 international quality system certification. Through strict procedures and high standards of auditing, the company has successfully passed the recognition of a "national high-tech enterprise". Gaston Company is gradually moving towards internationalization with its own strength and a global perspective.

Users with different needs will always be the coordinates we strive for and the driving force for constantly surpassing ourselves and striving for innovation! Gaston Company looks forward to sincere cooperation with friends from all walks of life at home and abroad to create brilliance together!

The company has been committed to product innovation for many years, focusing on the updating and upgrading of pneumatic motors. With fine concepts and continuous investment, it has created a creative design team and has designed multiple innovative pneumatic products. Currently, it has independent intellectual property rights and has obtained more than 30 product patents.

The company's main products include pneumatic motors and a series of products such as pneumatic hoists, pneumatic winches, pneumatic mixers, pneumatic emulsifiers, pneumatic explosion-proof pumps, pneumatic mixers, pneumatic fans, and industrial automation equipment pneumatic control system engineering developed based on specific production needs.

The company strictly follows the ISO9001 quality management system for product design, production, assembly, and testing. With the efforts of all employees, the company has passed the ISO9001 international quality system certification. Through strict procedures and high standards of auditing, the company has successfully passed the recognition of a "national high-tech enterprise". Gaston Company is gradually moving towards internationalization with its own strength and a global perspective.

Users with different needs will always be the coordinates we strive for and the driving force for constantly surpassing ourselves and striving for innovation! Gaston Company looks forward to sincere cooperation with friends from all walks of life at home and abroad to create brilliance together!

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى