Submit feedback

Pneumatic Chain Hoist: The Powerful and Reliable Lifting Solution

2024.10.22

2024.10.22

Industry News

Industry News

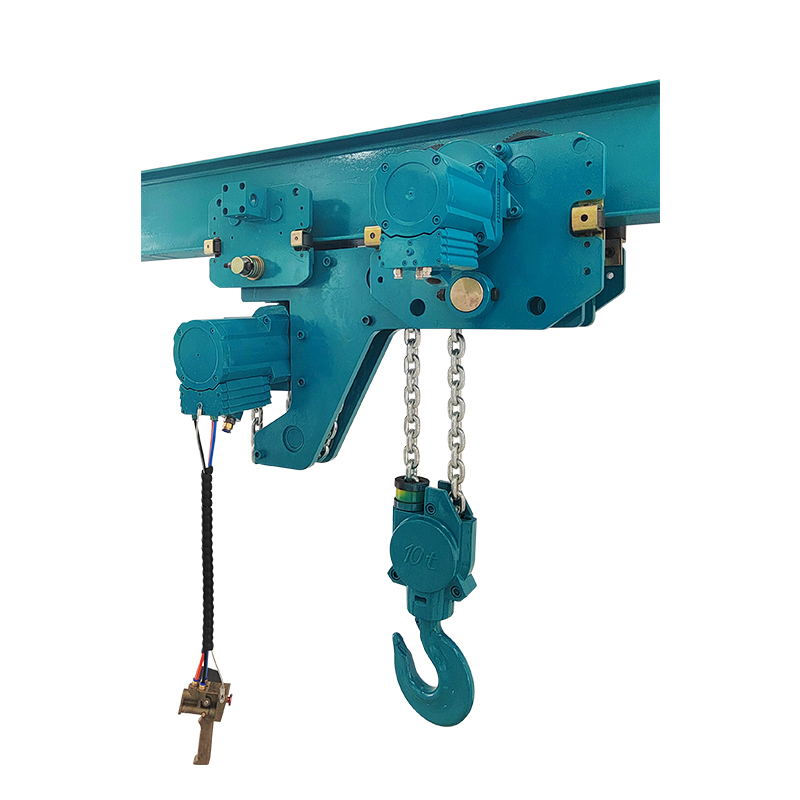

In the modern industrial field, lifting equipment plays a vital role, among which pneumatic chain hoist has become a leader in many applications with its unique advantages.

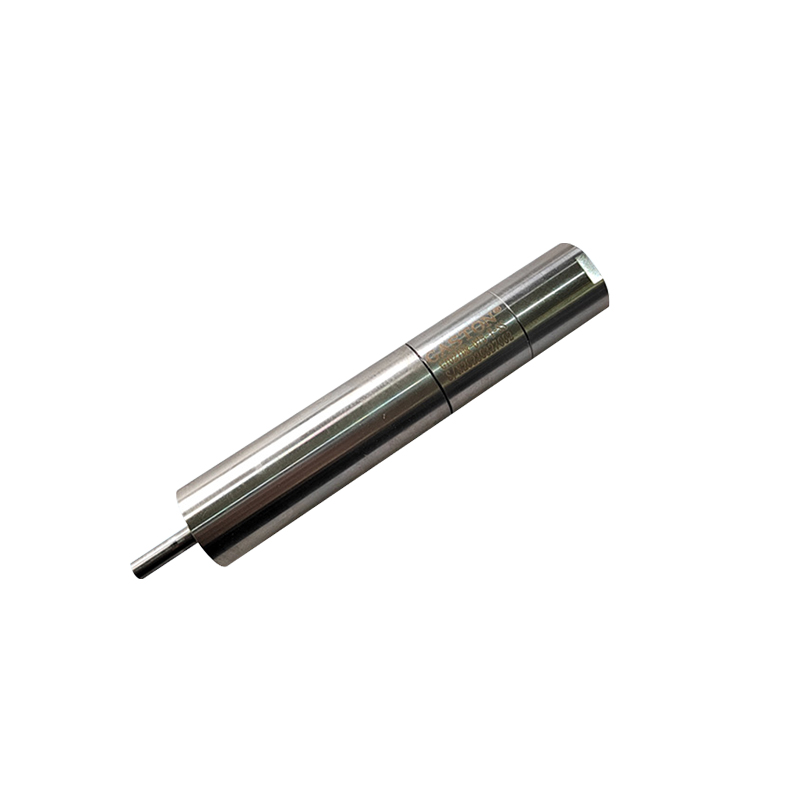

Pneumatic chain hoist is a lifting equipment that works on the pneumatic principle. It converts the kinetic energy of compressed air into mechanical energy, drives the sprocket to rotate, and then drives the chain to rise and fall, so as to lift or lower the object. Its core components include pneumatic motor, reducer, sprocket, chain and control valve. As a power source, the pneumatic motor has a compact structure and light weight, and can operate stably in harsh environments. The reducer plays the role of deceleration and torque increase, ensuring that the chain is stable and impact-free during the lifting process. The sprocket and chain are made of high-strength alloy materials, which are wear-resistant and durable and can withstand large loads.

A major feature of pneumatic chain hoists is their environmental protection and safety. Compared with traditional electric hoists, pneumatic hoists do not require electric drive, avoiding the risk of electrical fire and electric shock. The exhaust system of the pneumatic hoist has been carefully designed to effectively reduce noise and emissions, meeting the environmental protection requirements of modern industry.

Pneumatic chain hoists are widely used in many fields such as automobile manufacturing, aerospace, shipbuilding, petrochemical, food processing, etc. In automobile manufacturing plants, pneumatic hoists are often used in body assembly lines, which can efficiently and accurately complete the lifting and transfer of body. In the field of aerospace, the lightness and reliability of pneumatic hoists make them an ideal choice for the assembly and maintenance of aircraft parts. In the petrochemical industry, the explosion-proof performance of pneumatic hoists makes them a powerful assistant for handling flammable and explosive materials.

The technical advantages of pneumatic chain hoists are not only reflected in their high efficiency, environmental protection, safety, etc., but also in their flexibility and adaptability. Pneumatic hoists can be customized according to different working environments and needs, such as explosion-proof, anti-corrosion, high-temperature, etc., to meet the requirements of various complex working conditions. At the same time, the control system of the pneumatic hoist adopts advanced electronic control technology, which can achieve precise positioning and remote control, greatly improving work efficiency and convenience of operation.

With the advent of the Industrial 4.0 era, pneumatic chain hoists are also constantly undergoing technological innovation and upgrading. On the one hand, by introducing technologies such as sensors and the Internet of Things, pneumatic hoists can achieve intelligent monitoring and management, provide real-time feedback on equipment operating status and working data, and provide a scientific basis for equipment maintenance and maintenance. On the other hand, by optimizing the design of pneumatic motors and reducers, the energy efficiency and stability of equipment can be improved, energy consumption and noise can be reduced, and green production can be achieved.

In the future, pneumatic chain hoists will develop in a more intelligent, efficient, and environmentally friendly direction. On the one hand, by integrating advanced automation technologies such as machine vision and artificial intelligence, automated control and unmanned operation can be achieved to improve production efficiency and product quality. On the other hand, by developing new materials and manufacturing processes, the durability and reliability of equipment can be improved, the service life can be extended, and maintenance costs can be reduced.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى