Submit feedback

Pneumatic Chain Hoist: Revolutionizing Lifting and Hoisting Operations

2024.12.15

2024.12.15

Industry News

Industry News

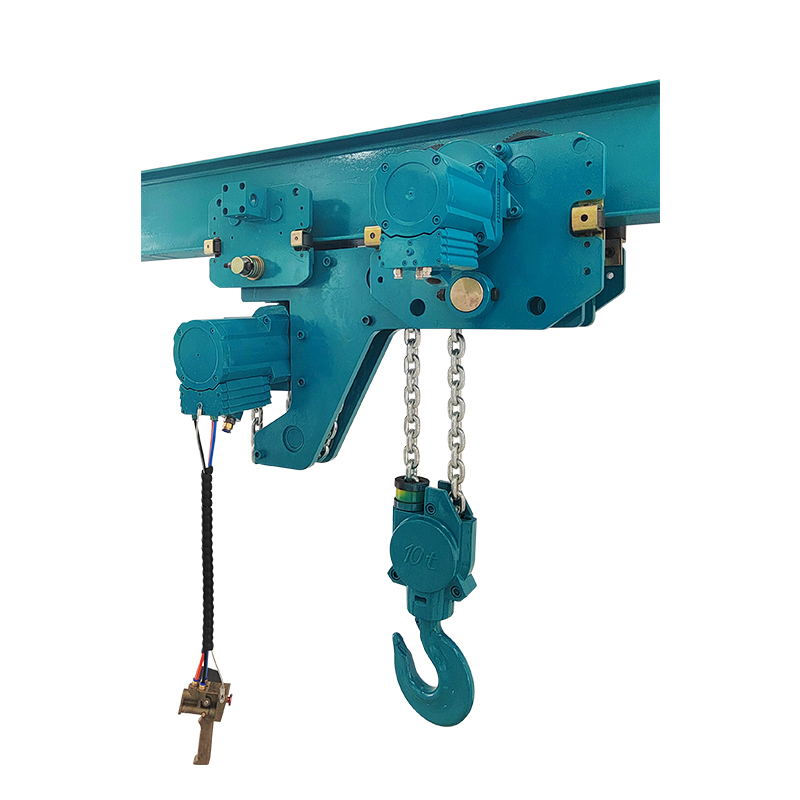

In industrial production, construction sites and various heavy-duty working environments, pneumatic chain hoists (Pneumatic Chain Hoist) are gradually becoming an important choice to replace traditional electric hoists with their unique working principle, efficient performance and wide range of applications.

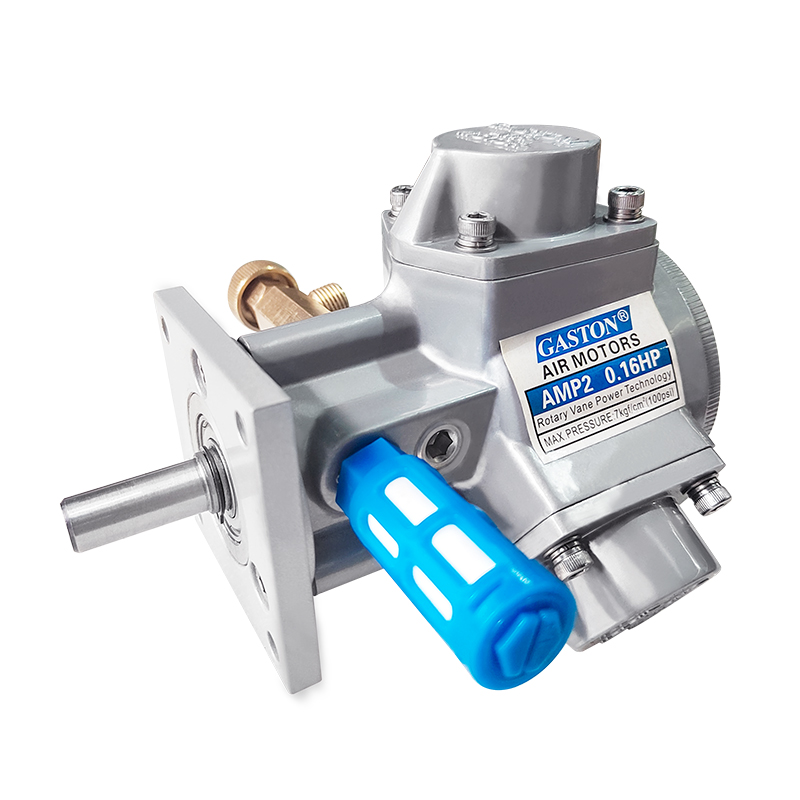

Pneumatic chain hoist, also known as pneumatic chain hoist, is a lifting device driven by compressed air. It usually consists of a drive motor, a reducer, a suspension assembly, a pneumatic main valve, an endless chain, upper and lower hooks and a manual pilot valve. These components ensure the stability and reliability of the hoist during the lifting process through precise design and layout.

The working principle of pneumatic hoists is based on the energy conversion of compressed air. When compressed air enters the pneumatic main valve through the main air pipe, it pushes the internal piston, thereby driving the rotation of the reducer and the endless chain. This process converts the energy of compressed air into mechanical energy to achieve the lifting of heavy objects. At the same time, the manual pilot valve allows the operator to accurately control the on and off of the airflow, thereby realizing the start, stop and speed regulation of the hoist.

The pneumatic hoist adopts the middle arrangement mode of suspension, and the motor and reducer are symmetrically installed on both sides of the suspension assembly. This design avoids tilting and swinging during the lifting process, making the hoist compact, light, stable and reliable in operation. In addition, due to the use of air as the power source, the pneumatic hoist has self-cooling ability, can work continuously in a high temperature environment, and will not generate electric sparks, so it has significant advantages in flammable and explosive environments.

Compared with traditional electric hoists, pneumatic hoists have many significant advantages. First, its power source is compressed air, and no electricity support is required, so it is more flexible in use, especially in environments where electricity supply is inconvenient or there are safety hazards. Secondly, the start and stop process of the pneumatic hoist is smooth, which reduces the impact on the load and improves the accuracy and safety of the lifting process. In addition, due to the air cooling system, the pneumatic hoist can work for a long time in a high temperature environment without being damaged by overheating.

Another important advantage of the pneumatic hoist is its low maintenance cost. Compared with the electric hoist, the pneumatic hoist has a simpler structure and fewer parts, so it is more convenient to repair and maintain. At the same time, since compressed air is used as the power source, pneumatic hoists do not produce oil or noise during operation, and cause less pollution to the environment.

Pneumatic chain hoists are widely used in various heavy-duty working environments due to their unique performance and advantages. In industries such as mining, electricity, cement, oil refining and offshore drilling platforms, pneumatic hoists have become indispensable lifting equipment in these environments due to their explosion-proof performance and high-temperature working ability. In the fields of aviation, papermaking, automobile manufacturing and refining, the precise control and efficient performance of pneumatic hoists also make them an ideal choice for lifting and moving heavy objects.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى