Submit feedback

Pneumatic Air Driven Mixers: The Power of Compressed Air in Mixing Technology

2024.12.22

2024.12.22

Industry News

Industry News

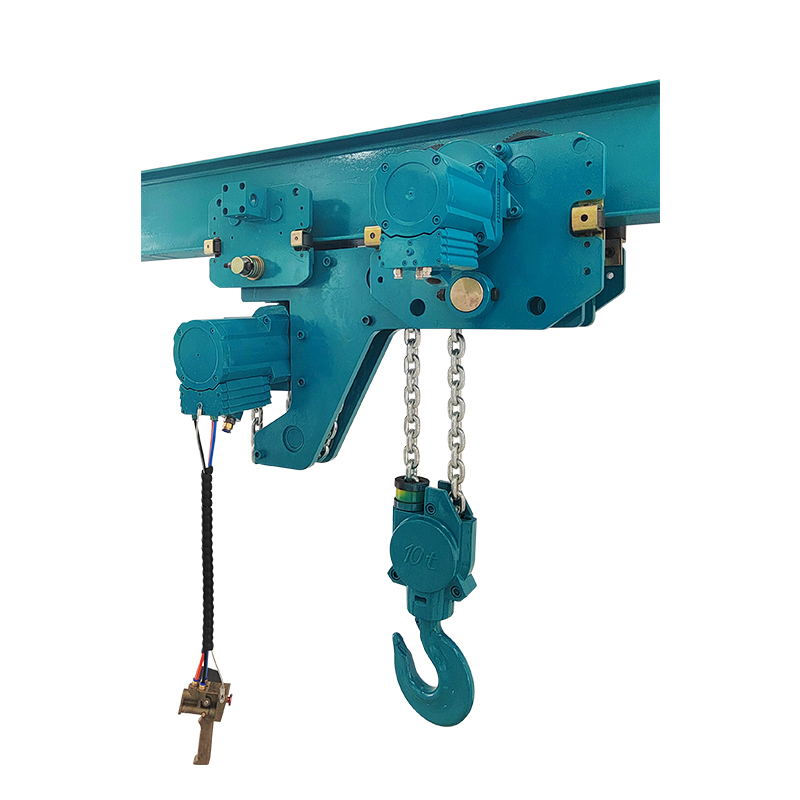

In modern industry, pneumatic technology has been widely used in many fields with its high efficiency, safety and flexibility. Among them, pneumatic mixers (Pneumatic Air Driven Mixers) play an important role in the petroleum, chemical, coating, ink, resin, medical, food, daily chemical and other industries with their unique advantages.

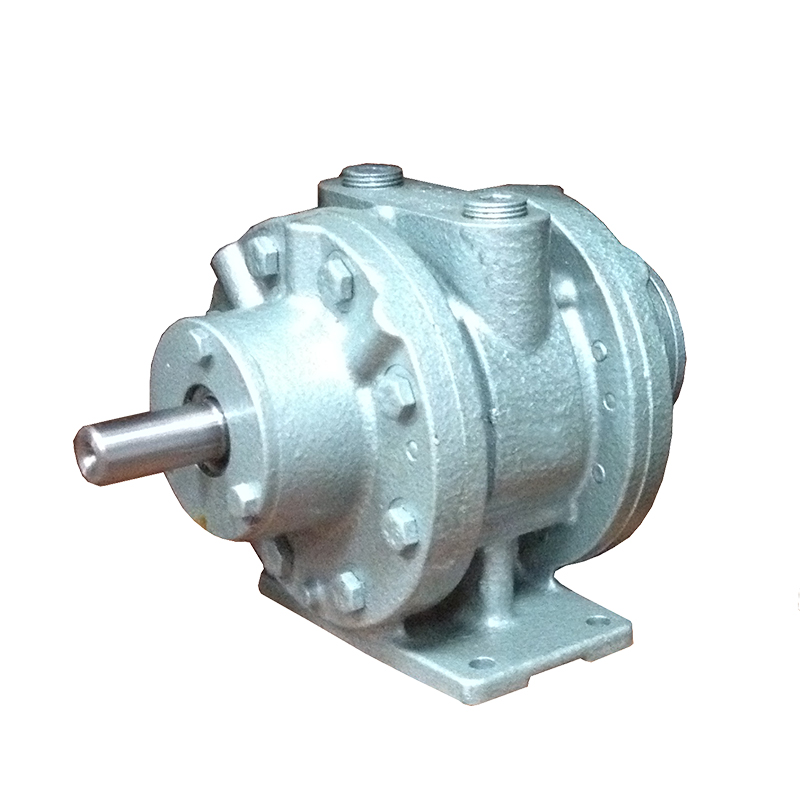

Pneumatic mixers are mainly composed of pneumatic motors, stirring shafts, connecting sleeves and stirring impellers. Pneumatic motors are the core power components of pneumatic mixers and can be divided into blade pneumatic motors and piston pneumatic motors. The blade pneumatic motor has a simple structure and can achieve high-speed mixing, while the gas consumption is high; while the piston pneumatic motor has a large volume and weight, high starting torque, suitable for low-speed mixing, and relatively low gas consumption.

Pneumatic motors are driven by compressed air, have a self-cooling effect, can run continuously for a long time, and will not generate sparks and high temperatures. In addition, pneumatic mixers can achieve stepless speed regulation by adjusting the air intake to meet different process requirements.

Advantages

Explosion-proof characteristics: Pneumatic agitators use compressed air as a power source, and have natural explosion-proof characteristics in flammable, explosive, dusty, humid and other harsh working environments, which greatly improves production safety.

Easy to adjust: By adjusting the opening of the air inlet valve or the exhaust valve, that is, controlling the flow of compressed air, the output power and speed of the pneumatic motor can be easily adjusted to achieve stepless speed regulation.

Flexible forward and reverse rotation: Simply change the air intake and exhaust direction of the pneumatic motor through the control valve to achieve forward and reverse rotation of the stirring shaft and change the stirring direction instantly.

Easy maintenance: The pneumatic agitator has a simple structure, easy maintenance, and a lubrication-free design. It does not require power, does not generate electric sparks, and is completely explosion-proof.

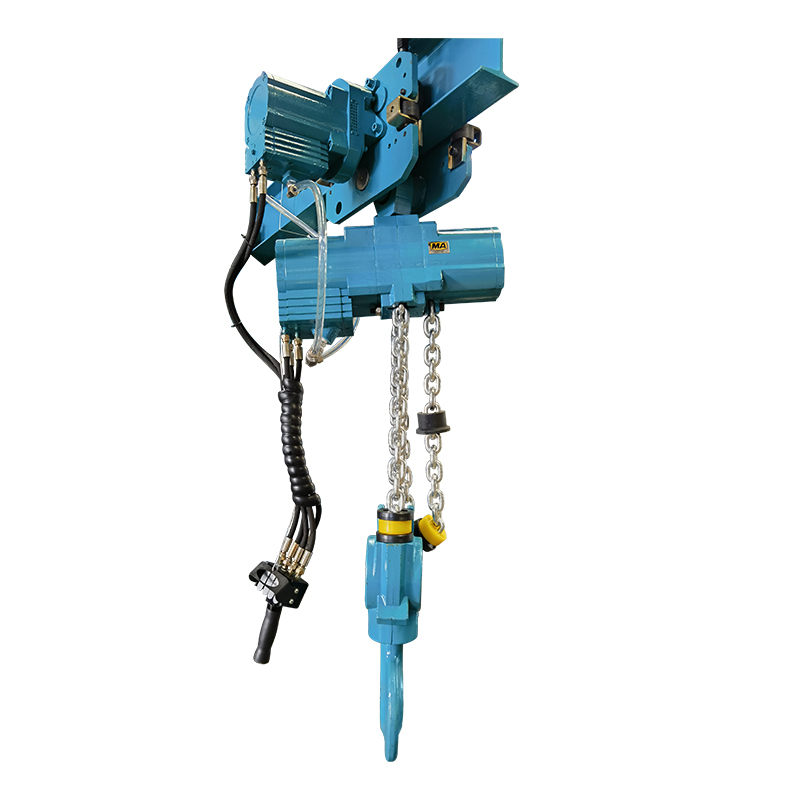

In the process of petroleum refining and chemical production, pneumatic agitators are widely used in the stirring of equipment such as reactors and storage tanks to ensure uniform mixing of materials and improve production efficiency.

Pneumatic agitators can achieve precise control and ensure product quality during the production and preparation of coatings and inks.

In the food and pharmaceutical industries, pneumatic agitators are widely used in material mixing, fermentation, stirring and other processes due to their explosion-proof and pollution-free characteristics.

In the production of daily chemical products, pneumatic agitators can achieve efficient and uniform mixing, improve product quality and production efficiency.

With the advent of Industry 4.0 and the era of intelligent manufacturing, pneumatic agitators, as an important part of automation control, will usher in new development opportunities. In the future, pneumatic agitators will pay more attention to the improvement of high efficiency, high precision, low noise and environmental protection performance. At the same time, with the integration of technologies such as the Internet of Things, big data and artificial intelligence, pneumatic agitators will achieve more intelligent control and management, improve production efficiency and product quality.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى