Submit feedback

Stainless Steel Pneumatic Pumps: The Versatile Workhorse in Industrial Applications

2024.10.08

2024.10.08

Industry News

Industry News

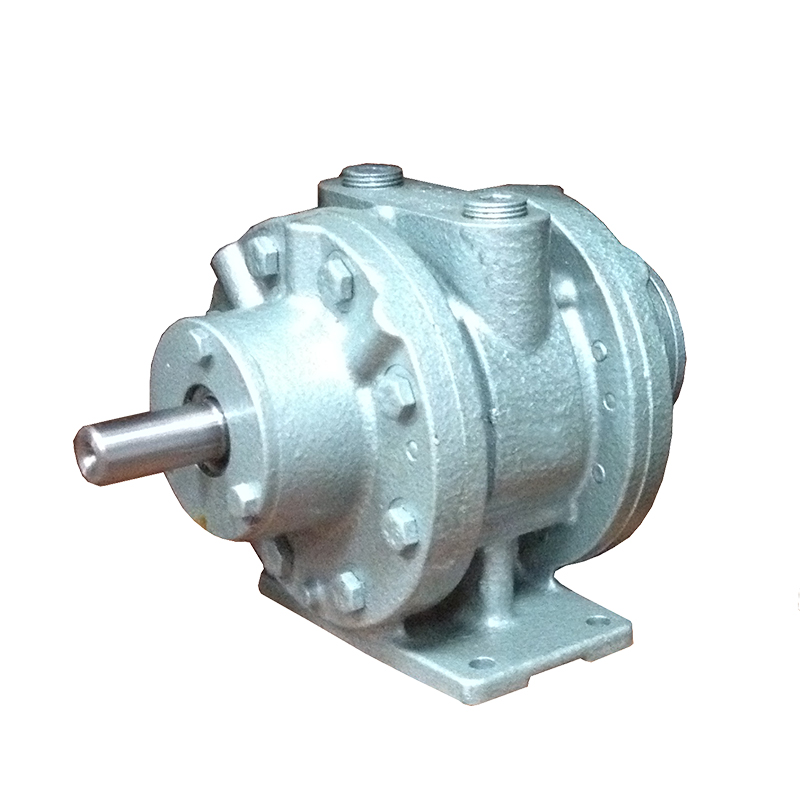

Stainless steel pneumatic pumps, also known as stainless steel pneumatic diaphragm pumps, have emerged as a pivotal component in various industrial applications due to their robustness, versatility, and reliability. Combining the corrosion resistance of stainless steel with the power of compressed air, these pumps are designed to handle a wide range of fluids, from corrosive liquids to high-viscosity, volatile, and toxic substances.

The core of stainless steel pneumatic pumps lies in their diaphragm design. These pumps feature two symmetrical working chambers, each equipped with an elastic diaphragm. A connecting rod links the two diaphragms, allowing them to move in unison. Compressed air enters the pump through an inlet fitting and distributes to the two working chambers, pushing the diaphragms and driving the connecting rod. As one diaphragm moves forward, the other moves backward, expelling the fluid from the opposite chamber. This synchronized motion is achieved through a valve mechanism that alternates the compressed air supply, creating a continuous pumping action.

The diaphragms' reciprocating motion alters the volume of the working chambers, causing two unidirectional ball valves to alternately open and close. This mechanism ensures continuous suction and discharge of the fluid, making stainless steel pneumatic pumps highly efficient and effective.

Stainless steel pneumatic pumps cater to a diverse range of fluids due to their material versatility. Pump bodies are typically constructed from materials such as aluminum alloy, cast iron, engineering plastics, and stainless steel. The diaphragms and seals can be made from materials like Buna-N rubber, neoprene, Viton, and PTFE, depending on the fluid being pumped. This flexibility allows the pumps to handle aggressive chemicals, corrosive acids, abrasives, and even viscous materials like paints, adhesives, and chocolates.

These pumps offer several performance advantages that make them indispensable in numerous industries.

The absence of rotating parts and shaft seals ensures that the pumped medium remains isolated from the pump's moving components. This feature is particularly crucial when handling toxic, volatile, or corrosive fluids, as it prevents leaks and environmental contamination.

Stainless steel pneumatic pumps do not require electricity, making them safe for use in hazardous environments. They are self-protecting against overload, automatically stopping when the load exceeds the limit and restarting once it returns to normal.

These pumps are straightforward to install, maintain, and repair. With minimal wear parts and no need for lubrication, they offer extended operational life and reduced downtime.

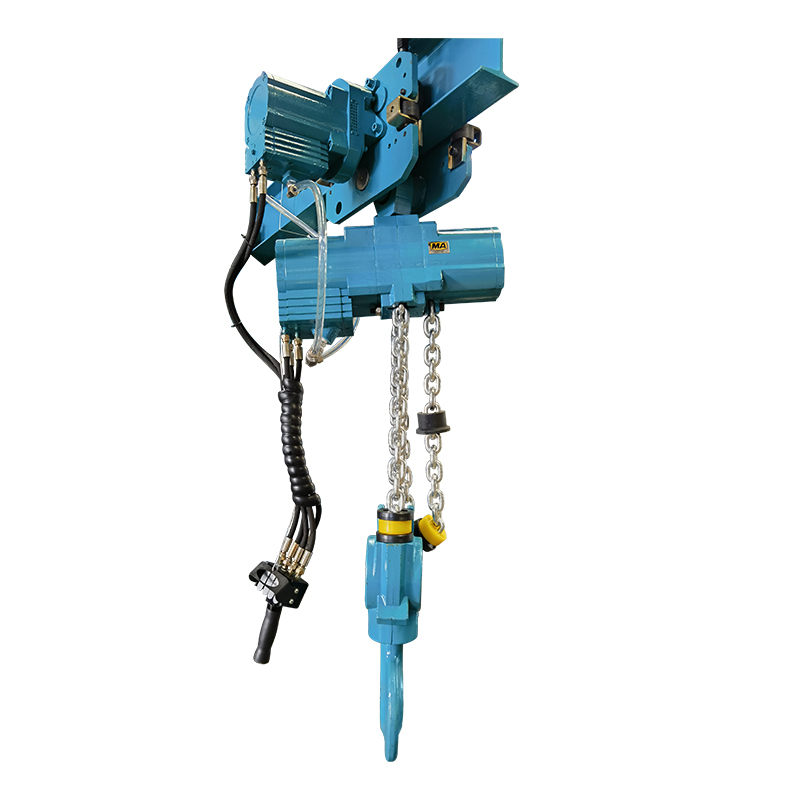

Stainless steel pneumatic pumps find extensive use in sectors such as chemicals, environmental protection, oil fields, pharmaceuticals, food processing, metallurgy, papermaking, electricity, and textile industries. They are ideal for applications involving the transfer of corrosive chemicals, fuels, food products, and waste materials.

Stainless steel pneumatic pumps represent a robust and versatile solution for handling diverse fluid types in various industrial settings. Their unique design, material compatibility, superior performance, and wide application range make them a must-have for ensuring efficient, safe, and reliable fluid transfer in modern industrial operations.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى