Call us: +86-0563-3366805

Email us:sales@shgaston.cn

- Home

- Product

- Pneumatic Motor Series

- Pneumatic Mixer Series

- HB Horizontal Pneumatic Mixer

- IBC Pneumatic Mixer

- QD 20-50kg Pneumatic Explosion-Proof Mixer

- SD Manual Lifting Pneumatic Mixer

- SL-A Four-Legged Mixer

- SZ Stretch Type Pneumatic Mixer

- TC Trolley Type Pneumatic Mixer

- Stainless Steel Pneumatic Mixer

- Stainless Steel Pneumatic Mixing Barrel

- Single Column Pneumatic Mixer

- Clamp-On Pneumatic Mixer

- Vertical Pneumatic Mixer

- Laboratory Small Pneumatic Mixer

- Portable Pneumatic Mixer

- Pneumatic Paint Mixer Machine

- Pneumatic Hoist Series

- Pneumatic Winch Series

- Pneumatic Fan Series

- Pneumatic Pump Series

- About Gaston

- Application

- Download

- News

- Contact

Web Menu

- Home

- Product

- Pneumatic Motor Series

- Pneumatic Mixer Series

- HB Horizontal Pneumatic Mixer

- IBC Pneumatic Mixer

- QD 20-50kg Pneumatic Explosion-Proof Mixer

- SD Manual Lifting Pneumatic Mixer

- SL-A Four-Legged Mixer

- SZ Stretch Type Pneumatic Mixer

- TC Trolley Type Pneumatic Mixer

- Stainless Steel Pneumatic Mixer

- Stainless Steel Pneumatic Mixing Barrel

- Single Column Pneumatic Mixer

- Clamp-On Pneumatic Mixer

- Vertical Pneumatic Mixer

- Laboratory Small Pneumatic Mixer

- Portable Pneumatic Mixer

- Pneumatic Paint Mixer Machine

- Pneumatic Hoist Series

- Pneumatic Winch Series

- Pneumatic Fan Series

- Pneumatic Pump Series

- About Gaston

- Application

- Download

- News

- Contact

Product Search

Exit Menu

Submit feedback

Stainless Steel Pneumatic Pumps: Driving Force Innovation in the Industrial Field

Home / News / Industry News / Stainless Steel Pneumatic Pumps: Driving Force Innovation in the Industrial Field

Home / News / Industry News / Stainless Steel Pneumatic Pumps: Driving Force Innovation in the Industrial Field Stainless Steel Pneumatic Pumps: Driving Force Innovation in the Industrial Field

2025.02.22

2025.02.22

Industry News

Industry News

In the rapidly developing modern industrial system, efficient, durable and adaptable fluid transmission equipment is one of the key elements to promote the production process. Stainless Steel Pneumatic Pumps, as a leader in this field, has demonstrated unparalleled advantages in many industrial application scenarios with its unique material properties and working principles, and has become an indispensable "heart" in many industries.

Stainless steel, with its excellent corrosion resistance, high strength and good hygiene performance, stands out among many materials and becomes an ideal choice for pneumatic pump manufacturing. In industries with extremely strict environmental requirements such as chemical, food processing, and pharmaceutical manufacturing, stainless steel can effectively resist acid and alkali corrosion, prevent pollution, and ensure the purity and safety of fluids. The high strength characteristics of stainless steel enable pneumatic pumps to withstand higher working pressures, extend service life, reduce maintenance costs, and provide solid guarantees for the company's continuous production.

The working principle of pneumatic pumps is based on compressed air as a power source. This feature gives it multiple advantages such as high efficiency and energy saving, simple operation, and easy maintenance. Compared with electric pumps, pneumatic pumps do not require complex electrical systems, which reduces the risk of fire and electric shock, and are particularly suitable for use in flammable and explosive environments. At the same time, by adjusting the air pressure, the flow and pressure of the pump can be accurately controlled to meet different process requirements and achieve flexible production scheduling. In situations where frequent starting and stopping are required, pneumatic pumps have a fast response speed and can quickly reach the working state, improving production efficiency.

The application range of stainless steel pneumatic pumps is extremely wide, covering almost all industries that require fluid transmission. In the chemical industry, they are used to transport various corrosive chemicals; in the food processing field, they ensure the safe transmission of food-grade fluids; in the pharmaceutical industry, their hygienic performance meets GMP standards and is an ideal choice for liquid medicine transmission. In many fields such as environmental water treatment, paint spraying, mining and metallurgy, stainless steel pneumatic pumps also play an irreplaceable role. Its strong adaptability comes from the flexibility of its structural design. Whether it is a high temperature and high pressure environment or a low temperature and low pressure condition, it can find a suitable pump type to meet specific needs.

With the advancement of technology, the design of stainless steel pneumatic pumps is also constantly evolving. Modern pneumatic pumps use more advanced sealing technology to reduce leakage and improve efficiency; intelligent control systems make pump operation more automated, reduce manual intervention, and improve production accuracy. At the same time, in response to the global trend of environmental protection and energy conservation, new pneumatic pumps pay more attention to energy efficiency in design, and effectively reduce energy consumption and carbon emissions by optimizing airflow paths and using energy-saving pneumatic components.

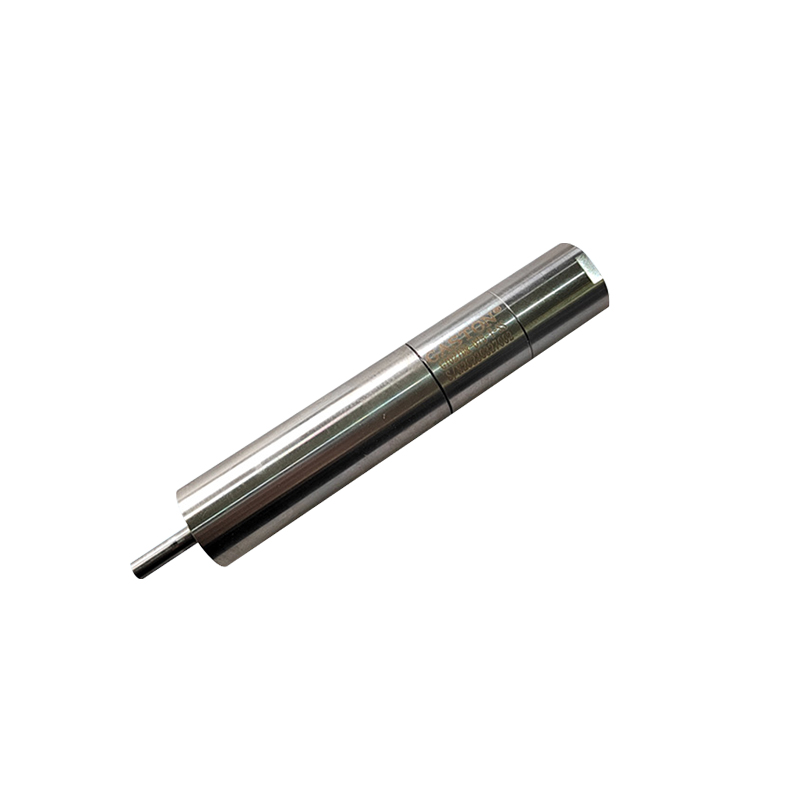

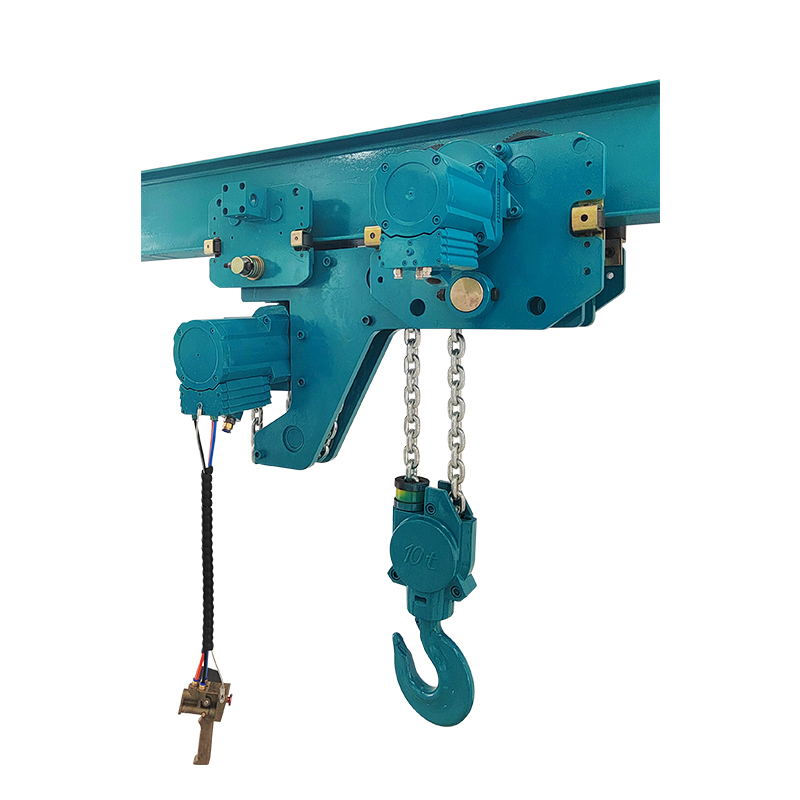

RECOMMENDED PRODUCTS

Quick Links

Products

CONTACT INFO

sales@shgaston.cn

sales@shgaston.cn +86-0563-3366809

+86-0563-3366809 +86-0563-3366805 / +86-13916933016

+86-0563-3366805 / +86-13916933016 3-B Songquan East Road, High tech Industrial Development Zone, Xuanzhou District, Xuancheng, Anhui, China.

3-B Songquan East Road, High tech Industrial Development Zone, Xuanzhou District, Xuancheng, Anhui, China.

Copyright© 2024 Anhui Gaston Precision Machinery Co, Ltd. All Rights Reserved.

Wholesale GASTON Pneumatic Motor Equipment Suppliers

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى