Submit feedback

How are air motors controlled?

2024.06.02

2024.06.02

Industry News

Industry News

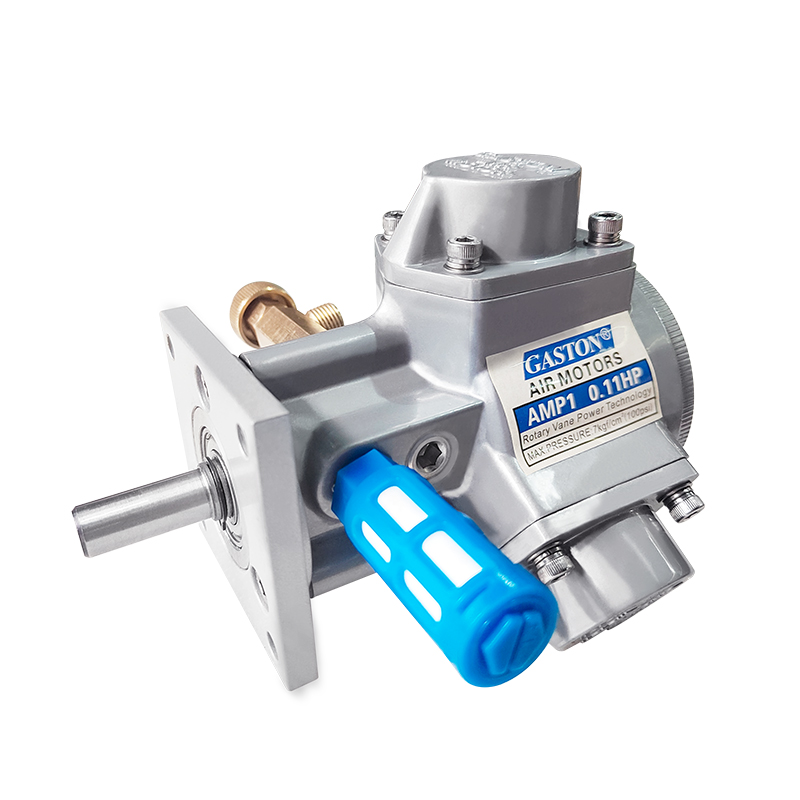

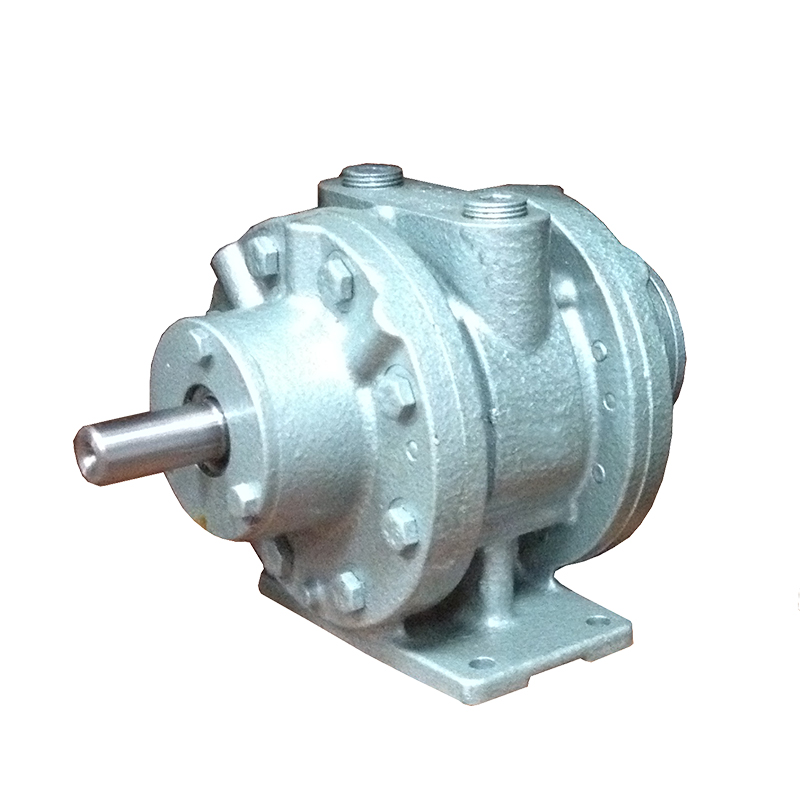

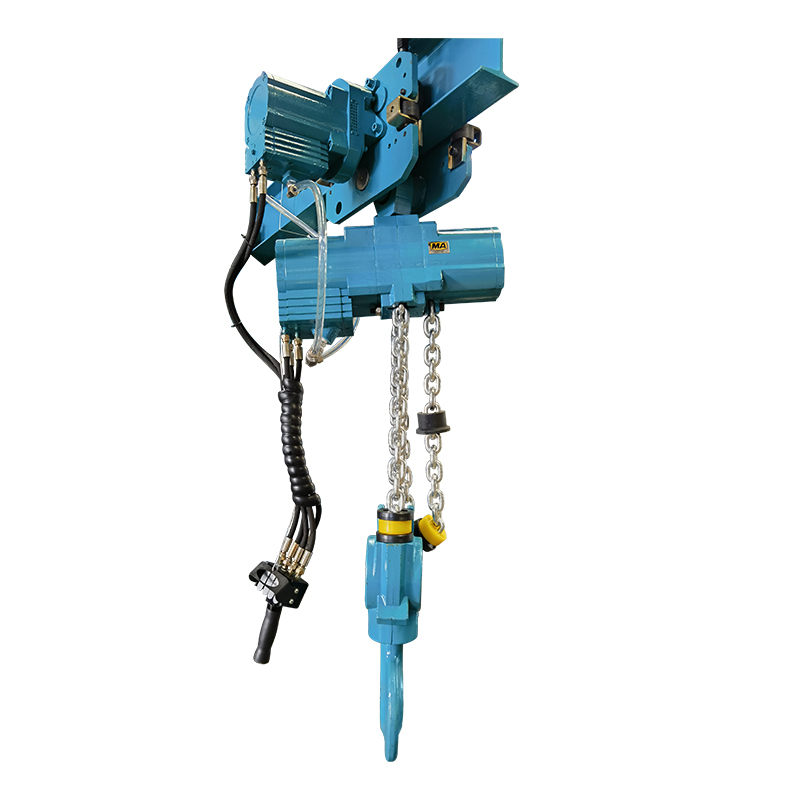

How are pneumatic motors controlled?

1. The air supplied to the motor must be filtered and depressurized. A directional control valve is required to supply air to the motor and rotate it when required. Such valves can be pneumatically, electrically, or mechanically controlled.

2. When the motor is used in applications where it does not rotate in both directions, a 2/2 or 3/2 valve is sufficient. For motors that can rotate in the opposite direction, a 5/3 or two 3/2 valves are required to ensure that the motor has compressed air supply and residual air is exhausted.

3. If the motor is not used for directional rotation, a flow control valve can be installed in the air supply line to adjust the speed of the motor. If the motor is used for reverse rotation, a flow control valve with an internal check function is required to adjust the rotation in each direction. The valve with an internal check function allows air to be discharged from the residual air exhaust port of the motor to the exhaust port of the control valve and then discharged.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى